Subproject A.5

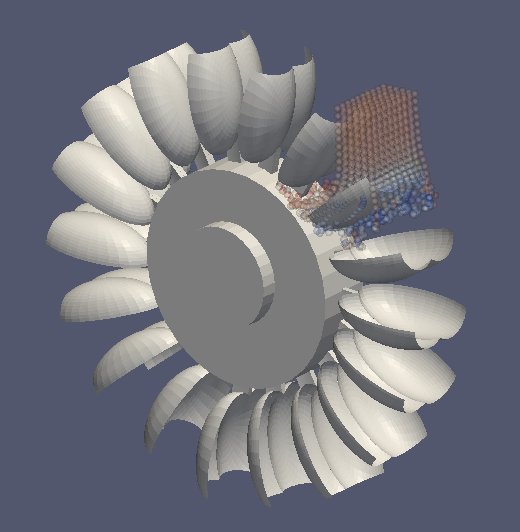

Simulation of Abrasive Damage Processes using Hybrid Smoothed Particle

|

|

What kinds of wear occur at flow-passage components of hydraulic machines?

Where do the abrasive particles sediment? How long will it take until deadlock and impact cause gradual alteration in state and shape of the influenced surfaces? These mechanisms should be analysed with a newly developed approach. For this purpose, the meshless methods smoothed particle hydrodynamics and discrete element method are coupled. Following the basic approach of these two methods the continuum is described with a large number of particles.

The longterm goal of this research project is to develop and improve the process of design and optimization in fields where experiments and measurements are not applicable. Therefore, computer simulations on this topic based on the new method are performed.

Further information about this subproject